Cocoa butter Silk is back

Viewing entries in

Tempering

Is a humidity of 70% too high to temper with?

Recently, I've been making honey chocolates (1 c cocoa powder, 1 c coconut oil, and 1/3 c honey) to remarkable success. However, my main issue is that the chocolate get soft (Though not melted) at room temperature, and it can get quite messy when someone picks it up to eat if it's not straight out of the freezer.

Tempering in the warm months

Reviewing the basics of tempering

I wanted to know what recommendations you have for making more soft chocolates.

Level: Novice

Reading Time: 12 minutes

I just read Dandelion’s new book and chocolate making seems very expensive. Isn’t there some other way make chocolate without a melanger. Wouldn’t a high powered vitamix work? How about the Champion juicer? Can’t I just run the sugar through there? It all seems so complicated. There should be a simpler way. I can roast coffee in a $10 popcorn air popper. Can I crack the beans In a corona mill and won’t that make chocolate?

Some of you long time readers might be a little confused with why I would answer these series of question when it seems really old news. The alternative was “What happens if you dip a cat in chocolate?” and well……

I have seen a large resurgence in these kinds of questions in the last couple months. New chocolate makers are coming in droves (of which I am thrilled by) and with it people seem to be trying to reinvent the proverbial wheel.

I in no way want to stifle questions, inquisitiveness and innovation but I also really want people to do a little research and maybe realize that nearly all of these questions have been asked before and answered (mostly with a 'no').

I want people to make chocolate. Keep that in mind. So ask yourself this. If there was a cheaper, simpler way to make chocolate, don’t you think I would be the first to announce it to the world? Really, I’m not ‘Da Man’ trying to keep secrets hidden. I've built Chocolate Alchemy on the philosophy that there are no secrets and I want to spread all I know.

I guess this is going to turn into a little review of bean to bar history interspersed with some of the questions. Let’s take it from the top down, going through each step of the process.

“You are selling beans from 2015. Aren’t they too old by now?”

I only sell beans that I’ve personally tested and verified. I make chocolate regularly and pull beans from our stocks once their flavor profile degrades. In some cases that is 1 year but many (most really) times it can be 2-3 years.

“Isn’t Criollo the best?”

They are just the rarest and generally the most mild. I hold by the stance there is no 'best', just your own personal favorite.

“Can I use an air popper like coffee to roast nibs?”

See the above discussion. I tried it and for a multitude of reasons it didn’t work. Mostly it has to do with scale and control.

“Won’t a coffee roaster burn my cocoa?”

No, you can turn it down.

“Will my chocolate taste like coffee if I use my coffee roaster?”

No, I have done it for years. Any coffee oils that might cross contaminate the cocoa would be absorbed by the husk which you winnow away. I’ve never even see that happen and I’ve used the same roaster for years.

“Can I use a home brewing mill to crack my cocoa?”

No, the gap (even adjustable ones) is too small.

“Have you heard of the Crankandstein cocoa mill? Why don’t you offer it?”

You could say I’ve heard of it. I invented it and had it built by Crankandstein. I no longer offer it as I find the Champion juicer does a better job for a similar price. Plus the Champion is multi-purpose. You can also make liquor with it.

“Doesn’t the Champion get to hot and destroy all the flavor of the chocolate? It seems like it would burn it”.

I discovered using the Champion Juicer for chocolate way back in 2004 and built Chocolate Alchemy and got this whole bean to bar movement going with it. If it had burned the chocolate or made it inferior I simply can’t imagine we would be where we are today. Yes, the chocolate gets warm, and even hot, but stays WAY cooler than when you roast. No, it does not harm the chocolate.

“Can I use the Champion 4000?”

I’ve not personally used one, but hear it works ok, but not as good as the 2000 I offer. And while I am talking about the Champion, there is a Commercial version but I have not found any difference in performance or longevity compared to the Household model, so I offer the less expensive household model.

“Do I have to use a melanger? It is so expensive. Can I use……”

I cut that off because of all the variations. You can insert Vitamix, blender, grain mill, and any other of standard household appliance and I will answer that I tried out every one of them over the years and would have told you if they worked. As it is, I specifically outline a bunch HERE that do not work. Again, I WANT you to make chocolate. If I could lower the financial bar, what possible reason would I have for not doing that? The answer is none.

I’m going to take this opportunity and say I appreciate that this is not an inexpensive hobby. But when I started down this chocolate making at home road in 2004, before there was a bean to bar movement, it was not even possible to make chocolate at home. Aside from no knowledge base, all the equipment was industrial. There were no melangers. The cheapest winnower was $2000 and did a huge 2 oz a minute. There were no roasters. A basic set up would have cost you $100,000 or more. Now a good setup is $1000. That is two orders of magnitude. Please keep that in mind is all I’m saying.

“I’ve read that melangers make inferior chocolate and that you need a mill and conche to make good chocolate.”

The WHOLE bean to bar movement was built on the stunning results of stone melangers. I think that evidence right there speaks for itself as an answer to that question.

“Why don’t you invent a small $100 melanger? I’m sure you would get a lot more people into chocolate making.”

I bet Apple would sell a lot more Iphone X if they were $50 too. I would have done it if I thought it was possible but there is a lower limit to material and building costs. And really it comes down to scale in this case. Although there are 1000s of melangers out there, I would bet there are millions of iphone Xs already out there. If I made 100,000 small melangers I could probably do it for under $100 each but there is that small issue of the $10,000,000 needed to do that. As big as the bean to bar movement gets, I don’t see it ever being worthwhile to make 100,000 melangers at one go.

“I’ve heard you can’t use a tempering machine with bean to bar chocolate, that it is too thick. How do you temper?”

I am baffled where that opinion came from. You can. Certain extra light roasts that retain moisture might be a bit thicker, and some makers don’t like using cocoa butter (which makes for a more fluid chocolate), which I don’t understand, but you absolutely can use a tempering machine. That said, they are expensive and I don’t see a reason not to hand temper or to use Silk which is nearly fool proof.

That is a selection of questions that have come in the last couple months. I said at the beginning I wanted to give you a basic history of bean to bar. Dandelion’s book showed the successes very well, but what they didn’t describe (nor was it their place to) was the multitude of failures I went through. It would be impossible for me to tell you everything I tried but know that if it was a common household item, I tried it and if you don’t see it as an option, it is because it failed. And when I say failed I mean were too expensive, too DIY, too cumbersome, too hard to work with or literally just failed.

What are some of those things that didn’t work ?

- Ice cream maker (conche)

- Rock tumbler (refiner/conche)

- Air popper (roasting)

- Ball bearings in mixer (ball mill refiner – expensive)

- Rolling pin (cracker)

- Mortar and pestle (well, becaue)

- Hand peeling (too hard)

- Corona type mill (poor results)

- Champion Juicer (refining sugar – fail)

- Champion Juicer (winnowing - hard on machine and tasted bad)

- Vita-Mix (burned the chocolate)

- Other Juicers (ride up and fail)

- Home convection ovens (under powered)

- Meat Grinders (crackers and refiner)

- Food processors (refiner)

- Grain mills (cracker and refiner)

- Coffee grinders (refiner)

- Indian Wet Grinder (burned out, but we modified them to the Melanger you now know)

And that is just a sampling. Various other Rube Goldberg type contraptions were tried and there were many variations of those above. All that and more brought us to this place at this time where the web is full of free information on how you can get into chocolate making for the barest fraction of what it would have cost 20 years ago.

By all means keep trying though….but maybe not the same things others have tried and proved doesn’t work. There is that semi-urban myth that the definition of crazy is doing the same thing over and over expecting a different result. Try not to be crazy.

Just like they say there are no new ideas for story lines anymore, I am pretty confident there are no longer any obvious solutions for making chocolate simpler and significantly less expensive than there currently is.

Regardless, keep experimenting, making and asking questions.

Cheers.

It is about aging or blocking the chocolate right after the melanger/conching.

I have always blocked them untempered for about 2 weeks before melting them for use. But I heard some professional chefs said they age them in tempered form.

Questions:

How can I make chocolate with honey? -- 'The Updated Answer'

So why am I going to answer it again? It boils down to the scientific method. Science, good science, by its nature changes and evolves as we learn new things. It does not necessarily invalidate previous findings completely. It refines it and fine tunes it. To that end, I have somewhat a new answer to this question in that it appears (note the disclaimer for future updates of failure) that I have successfully tempered chocolate with honey in it.

Level: Novice

Reading/watching time: 4 min

Today I’m going to hit a few short questions about tempering and cocoa butter that have cropped up the last few weeks.

I usually need around 10 lbs of chocolate around the holidays, to spread on homemade English Toffee. I do temper the chocolate before I use it, but I was wondering if I can store the freshly made chocolate in bulk without tempering until I need it. Then temper and use it as needed.

If you are cooking with your chocolate where it is going above 100 F (Toffee goes over 200 F) you don’t need to temper as your temper will just be destroyed anyway. You can store your chocolate untempered until you need it. Just keep it cool and dry and sealed. There is no need to refrigerate or freeze.

Do I have to store my Silk in the freezer?

No, sealed, cool and dry is just fine.

I am confused about using silk. When do I lower the chocolate to 82 F and raise it back up to 88 F?

This one, somehow, as come up A LOT. Using Silk is a method of tempering unlike any other. Lowering chocolate to 80-82 creates Type V seed. Silk IS Type V seed. So it is more akin to any seed tempering method you use except you use a higher temperature (92F vs 88F) because the silk is pure and aggressive and can handle the higher temperature. So you don't ever lower and raise the temperature. You add the silk at 92-93 F and you are done.

What temperature do I have to use for milk chocolate if I am using Silk to temper?

The beauty of silk is that you don’t have to change your working temperature at all when you change chocolates. It is always 92.5 F.

I have used untempered cocoa butter to temper my chocolate with moderate success. Why do I need to use silk?

I’ve heard about this. It can work some of the time as you are finding. And sometimes it fails, as you are finding. The reason is that solid cocoa butter has some Type V naturally in it. If there is enough you can add it to your chocolate at 88 F and have a fine temper. The temperature destroys the non type V crystals and the remaining V acts as seed. But you have way to know or control how much V is there and in some cases there isn’t enough and your temper fails.

How important is it that the cacao butter be from the same region as the cacao bean?

I personally don’t think it is important at all from a flavor perspective. And unless your sweetener is also from the same origin, it is just silly from a ‘single origin’ perspective. I’ve seen WAY too many bars claiming 100% single origin and make a huge deal about pressing their own butter only to use a sugar from somewhere else.

The cocoa butter I ordered arrived melted. Is it ruined?

As long as it is not Silk (melting ruins the temper) your cocoa butter is fine.

We've noticed that different beans seems to have different amounts of intrinsic oil. The Peruvian Maranon seems to have quite a bit of oil and produces a chocolate that flows very easily but it tricky to temper correctly. Is there a way to know in advance the amount of oil in a bean so we can adjust the amount of cocoa butter we add?

In one of your articles you mentioned you like silk tempering more than chocolate seed tempering because of the strength of type V crystals in tempered cocoa butter. Can a chocolate tempered with chocolate seed have a chance of blooming because of the seed? I'm not sure if my last question made any sense but all I'm trying to understand is why chocolate seed crystals are not as good as silk seed crystals?

I am really sorry but I keep reading all the different ways I can temper and I am so confused. I don’t know which way to pick. It does not make sense that they can all work. How should I temper my chocolate and do I have to do it right out of the melanger? Will it be ruined if I don’t?

I use a Chocovision Delta to temper chocolate and have two questions:

(1) In using the seeding method (with tempered chocolate from the bag or from a bar of the same chocolate), I learned that it doesn't take very much seed for the chocolate to test as in temper--not the 30% or so that many (most?) people recommend.

I have tried making a milk chocolate with coconut milk powder but it is really soft and it is driving me crazy. I want the flavor really strong so I used 35% coconut power but it won’t set up. Should I use less cocoa butter? I put in about 8 oz to a two pound batch. I’ve even tried tempering it and it stays soft.

It looks like you ended up with the perfect storm of a recipe to just not behave in a cooperative fashion. You both have too much fat in the recipe and too much of it is coconut oil. Let’s see if we can get you a good coconut milk chocolate recipe that is still strongly flavored.

Today is just a small laundry list of announcements, some of which I would like your opinions on. There is no Ask the Alchemist because my queue is empty.

Ask The Alchemist #181, Question: Have you ever tried tempering chocolate with a Sous Vide?

Ask The Alchemist #180, Question: Have you ever tried tempering chocolate with a Sous Vide?

Level: Alchemist

Reading time: 20 minutes (if you are lucky)

Question: Time? Things are considered tempered when you take a test strip cool it and it has the characteristics you want. My question is does this happen rapidly, say 95% of the fat is in “V” at 10 mins, or is “tempering” when say 50% of the crystals are in the correct form. Does extending the time at temperature to say a day or 2 get significantly closer to 100% in V? Does this make a difference? You probably reach a point of diminishing returns, just curious how much science has been applied to this voodoo…

Funny you should mention voodoo. As I am going to take this into the exact opposite direction and define tempering in technical terms.

It’s worth noting that as I think of all I want to convey I feel like the philosopher who has attained enlightenment from the study of a butterfly wing and now wants to convey it to everyone….and takes page after page explaining it and ultimately fails because you usually can’t explain deep concepts quickly or easily. Regardless….onward.

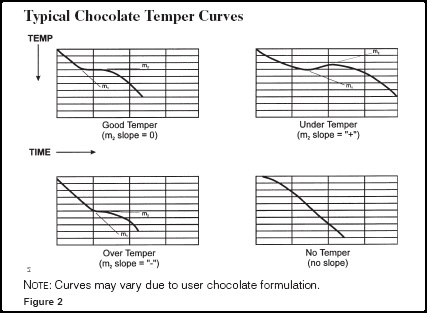

Chocolate is tempered properly when the inflection point of the of a temperature vs time cooling plot has a slope of zero.

And I suspect that doesn’t mean or explain anything to most of you. If you have a look around the internet you will find this old school image pretty quickly.

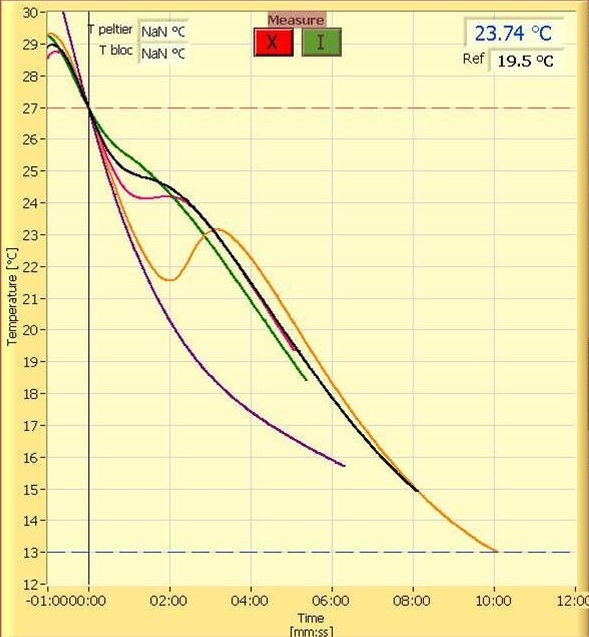

Digging a bit deeper and you can find something like this that shows real data in a form more of you can relate to.

In both cases they are showing plots of chocolate in different stages of temper, from untempered all the way to over tempered.

And I want you to read that last line again. There is something very important there that takes many people many years to realize. The first epiphany as it were. Over tempered. Chocolate can be over tempered. Understandably a large number of people think you want 100% temper. All Type V crystals. But that isn’t the case. You want a balance.

So that answers a part of your question. Or more to the point, it sheds some light on some of the assumptions you have made about tempering. That it is an end state. Sort of like absolute zero. And maybe it is. The key here is understanding that IF the perfect temper is analogous to absolute zero, then your goal is NOT absolute zero, but some temperature above that.

Try and let that sink in. I’ll try and explain why that is at the end.

But before we get deep into all the revelations that those plots can give us, let’s take a few moments and talk about what you are seeing there.

WARNING – SCIENCE AHEAD

Pretty much all of tempering is predicated on the concept of crystallization.

The following concept is one you need to wrap your head around.

Solidifying fat crystals give off heat in the same way dissolving salt crystals take in heat. These are the two sides of the same coin or concept.

That doesn’t make sense? This puts it into tangible terms.

If you make ice cream the old fashion way, you will recall you mix ice with salt. Remember that? Do you know why? Solid salt is just sitting there. It has low energy. Salt in solution is moving around. It has more energy. That energy has to come from somewhere. In the case of your ice cream and ice, it comes from the temperature of the system. Ice cream, ice and salt separate are all at 32 F. If the salt needs energy to dissolve, then it has to steal it from somewhere so it takes it from the only place it can; the temperature of the ice cream and ice. The result is that those temperatures drop to something under 32 F as the salt dissolves and your ice cream solidifies.

Got that? The whole point is to melt a crystal it has to take in heat. Therefore the opposite is also true. To form a crystal, heat is given off. This heat is called the heat of crystallization. To go all science and geeky on you:

“Heat of crystallization or enthalpy of crystallization is the heat evolved or absorbed when one mole of given substance crystallizes from a saturated solution of the same substance.”

Let’s bring this back to chocolate and set the stage. You are in the process of tempering your chocolate. You have either made or introduced seed to your untempered chocolate. For the sake of discussion, let’s call it 31 C. You pour it up into your mold and it starts to cool and eventually set up.

If we peek behind the curtain, and can monitor the temperature and crystals we are going to see the temperature start to drop. That is just the natural cooling of the chocolate. Energy is being given off to the atmosphere or maybe your refrigerator. At the same time, the seed of Type V crystals are going to start propagating or growing.

And now the fun part (did I mention I’m a retired chemist who finds this fun?).

We can make a prediction. As the crystals start to form we know (see above) that they are going to start giving off heat to the surround chocolate. And what is that going to do?

Very good. The temperature is going to rise.

And if we record those temperatures and the time, and then plot them, what is it going to look like? It is going to be a decreasing line (the temperature is falling initially because it is in the refrigerator or whatever) then, (oh, I’m so excited) since those crystals are giving off heat, (I’m virtually giddy here) the line is going to level off or maybe (shaking with geek excitement) even go back up! Then, once all the crystals are formed and no more heat is being evolved (yep, pulled in a science word there) the temperature will continue to drop to whatever the ambient temperature is.

Do you have that image in your head? Hopefully, it looks a LOT like this:

Which, wow, looks pretty much identical to the plot at the beginning for properly tempered chocolate!

Science!!! (giddy again….calming down…. )

Okay, I’ve calmed down for the moment. Hopefully you have the concepts down and we can talk about what they mean.

The first thing I want to address is that a zero slope (that flat spot) is nothing special. It is empirical meaning that it is just lucky coincidence that the majority of we humans like our chocolate when it is tempered at a zero inflection.

If you go back to the top and have a look at the curve of untempered chocolate you will notice it is basically a straight line pointing down.

“But alchemist, even bloomed chocolate has crystals. Type III, IV and V. Don’t they have a heat of crystallization and wouldn’t they cause some heat rise?”

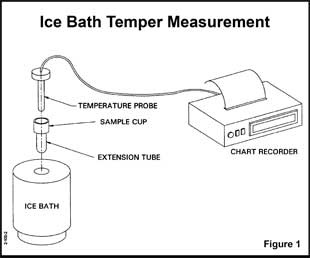

I am proud of you for making that connection. It is 100% true. IF…and this is where I didn’t play straight with you…we were truly measuring the temperature of your chocolate as it set up. But that is not what those plots are from. They are actually from a special setup that measures the degree of temper in a chocolate. It basically looks like this:

This image and the text below on It’s workings is from Ticor systems

“Their operation is quite simple. A cup-like opening at one end of a long metallic (copper) tube is filled with a chocolate sample. The other end of the tube is inserted in a mixture of ice and water held in an insulated container. A temperature probe (thermocouple in early versions) is then inserted into the chocolate. Since the chocolate sample is above 85°F and the sample holder is attempting to reach the temperature of the ice bath (a questionable 32°F), the chocolate gives up heat to the holder and is cooled to solidification.”

The key difference here is the ice bath and that in a degree of temper analysis you are forcing the chocolate and temperature down quickly along a reproducible path (because is a constant temperature and the system is insulated). The consequence of this is that you can see deviations easily and you are literally forcing the chocolate to solidify without crystallizing. Because no crystallization is happening, no heat is given off and no rise in temperature is noted.

Got it? Good!

And now we can talk about some of those bits of enlightenment that fall out of these graphs.

If you look at the 2nd graph above with all the overlaid plots you see a spectrum of non-tempered curves all the way to over tempered. This means tempering is a continuum and what falls out of that is that tempering is not a discrete state but a process and because we can have a full range of tempers we can have variables that we can adjust in a predictable manner to give us those final degrees of temper.

What are those variables? Well one big one should be obvious. The amount of Type V seed you have present and the original question hints at that. And that makes sense. The more seed you have, the more energy that is given off in a set amount of time and the more the cool curve tips up. Likewise, if you don’t have enough, it doesn’t tip up enough, the slope of the line doesn’t make it to zero, and you have under tempered chocolate, and if it is under tempered too much, it can bloom.

So, is time something you can manipulate? Will more time (2 days?) give you a higher degree of temper because more seed is formed? It certainly seems like it might be, and it can be, but it turns out that it isn’t practical. And the key is understanding that time is only helpful if it is your only variable. And in many cases it isn’t.

If you are tempering from scratch it is useless. Why? Because when you bring your chocolate down to 80 F or so and form seed, how much you form is varies with how fast you reduce the temperature and the ambient temperature. Without being able to control those exactly, you will have different amounts of seed (which you have no way of knowing) and that basically means you are starting from a different point in the tempering process each time so you can’t get to the degree of temper by measuring time.

If that isn’t clear, think of it as getting a car up to 60 mph (perfect temper, zero slope inflection) from a random unknown speed with only a stopwatch. It can’t be done. There are too many variables. How fast are you going (how much seed initially), how much are you accelerating and how do you measure it (what is the ambient temperature) and are there hills that you have to go up or down (how much heat loss do you have).

This is why hand tempering can be a series of failures until you both get a feel for how fast 60 mph is and you get used to the road (i.e. your techniques and conditions get VERY reproducible).

So what are you to do? You use some form of seed. And a tempering machine or water baths if you can. Neither is magical. They are nothing more and nothing less than variable control and management.

When you use seed or silk you starting with a known amount of seed, and better yet (analogy shift warning) your speed IS 60 mph and you just have to maintain it by watching the speedometer (your temperature).

If you want a lower degree of temper, you use less seed/silk. If you want I higher degree of temper, you use more. That simple.

So, it was probably hard to miss that I mentioned both seed and silk. The distinction is that the former is tempered chocolate and the latter is tempered cocoa butter. And they produce different tempers. Not just different degrees of temper, but actually different types of temper.

S. Beckett (The Science of Chocolate) notes this:

The temperature at which the inflection on the curve occurs is very important. The higher the temperature the more mature the crystallization and the higher the temperature at which the chocolate can be used for moulding and enrobing.

Silk makes for a more mature crystallization and is my personal favorite way to temper (video of that coming up). You can see this by how it is used. You mix it in at around 93-94 F. You use significantly less (0.5-1%) than you would tempered chocolate (20-30% many people recommend) and it propagates very fast through the chocolate, setting up quickly and with a particularly high resistance to blooming. And if you were to run a cooling curve on it you would see it produces the inflection point at a higher temperature correlating with a more mature crystal.

Is this all helpful day to day? I personally think it is since I wrote it. How? I think 90% of the help it gives is taking some of the mystery out of tempering (after you reread it a few times). It is just variables and if you grasp that, you can start to look for variables in your process and eliminate them or at least identify them when something goes awry and you chocolate blooms.

Can your or should you set up your own temper meter? If you find it fun and like the hard data, by all means do it. It isn’t hard. It is basically a thermometer and an insulated ice bath. You will probably have to play around a little with your sample size to get a flat line for untempered chocolate but that is about it. But of course you don’t have to. Hell, I LOVE this stuff and have not done it. But you can.

Oh, one more thing.

Remember I said I would explain why you don’t want an absolute temper? It’s really kind of simple. Mostly it is because you are a person eating chocolate and not a chemist striving for a perfect beautiful crystal. You are not looking for perfection in structure. You are looking for perfection in mouth feel. You are looking for an experience. You are looking for that perfect state where the chocolate is smooth and melts easily in your mouth. That point of state that allows maximum release of flavor and enjoyment. You are looking for the perfect tipping point where it is almost bloomed and almost too hard.

You are looking for balance.

I hope that was enough science to this voodoo we call tempering.

Welcome to the art AND science of chocolate making.

Level: Alchemist

Reading time: 7 min

So I have the revolution X chocovision tempering machine.

I am noticing at our apartment temperature being an average of 74F our chocolate does not hold nearly as well as others. I have a bar from fruition, rogue, dandelion, etc etc all at about the same 70% ratio and they seem to hold their temper so much better. Some don't use any cacao butter while others I can tell by texture use quite a bit.

I use these big blobs or "brains" I call them for seeds, I use them over and over but they are all white and flake apart when I put pressure on them... Is it because they aren’t in perfect temper why the resulting chocolate isn't coming out and holding that glossy black temper for a long time?

I just notice it gets a slight white film on it after a few weeks and the texture gets a tad funky..

Just so you know I am also using the temper 1 setting, so seed out at 90F and molding at 88.7F and then in the fridge to harden.

Should I be using the temper 2 setting where it drops it down and then back up to 88.7? Since the quality of my seed is pretty shit? Just figured I would ask. I am going to experiment as I just read through your illustration of tempering (great job by the way, the best most clear description I have seen yet)

If I just let the chocolate sit at room temperature it comes out really streaky and white

I figured 74F is just too warm, but based on your illustration it seems the temper might be off?

OK, tempering troubleshooting it is today.

For those not sure what is going on here, the method here is a mixture of a way I found works under certain conditions and using a tempering machine with seed. You can read the whole method here. http://chocolatealchemy.com/illustrated-tempering/

It entails using freshly crystallized chocolate as seed for tempering. Go read it. I won’t bore you here repeat it all.

Your issue appears to be that you have combined methods and are storing and using old bloomed chocolate instead of the freshly solidified chocolate that I call for. That is clear, aside from you saying it of course, is because it is white and crumbly. Forget “not perfect temper”. These are fully bloomed and devoid of any temper. Just because you call it seed does not seed it make.

The key to making my method work is that the seed portion that you use must be relatively fresh. In this state, there is a lot of Type V crystals. When you put this into your melted chocolate at 90-95 F, all the other types melt and you are left with a substantial quantity of Type V that acts as real seed and you get a good strong temper.

In old bloomed chocolate the amount of Type V has gone down significantly. As bloomed chocolate ages, there is solid state conversion. Type V converts to both IV and VI under certain conditions and this most likely is what is causing your issue. Those blob/brains are your indicator that your have Type VI. The Type VI melts at even a higher temperature than Type V, so there is no way to get rid of it without destroying your remaining Type V also.

I can’t really speak for your tempering machine’s settings as I don’t know them. Regardless, going down to 80 and back up won’t fix your issue if you are using Type VI contaminated seed unless you go all the way up to 100 f and then back down, which negates the whole reason for seed.

My recommendation then is to toss your crumbly not-seed chocolate and start fresh. And after that, instead of using this current method, there is no reason not to just reserve a bar of well tempered chocolate as your new seed.