Level: Apprentice

Reading Time: 8 Minutes

I'm interested in buying your winnower but I am going to use the crankandstein instead of the champion to crack my beans. I noticed your winnower is connected to a champion. For lack of better words, what are my options here?

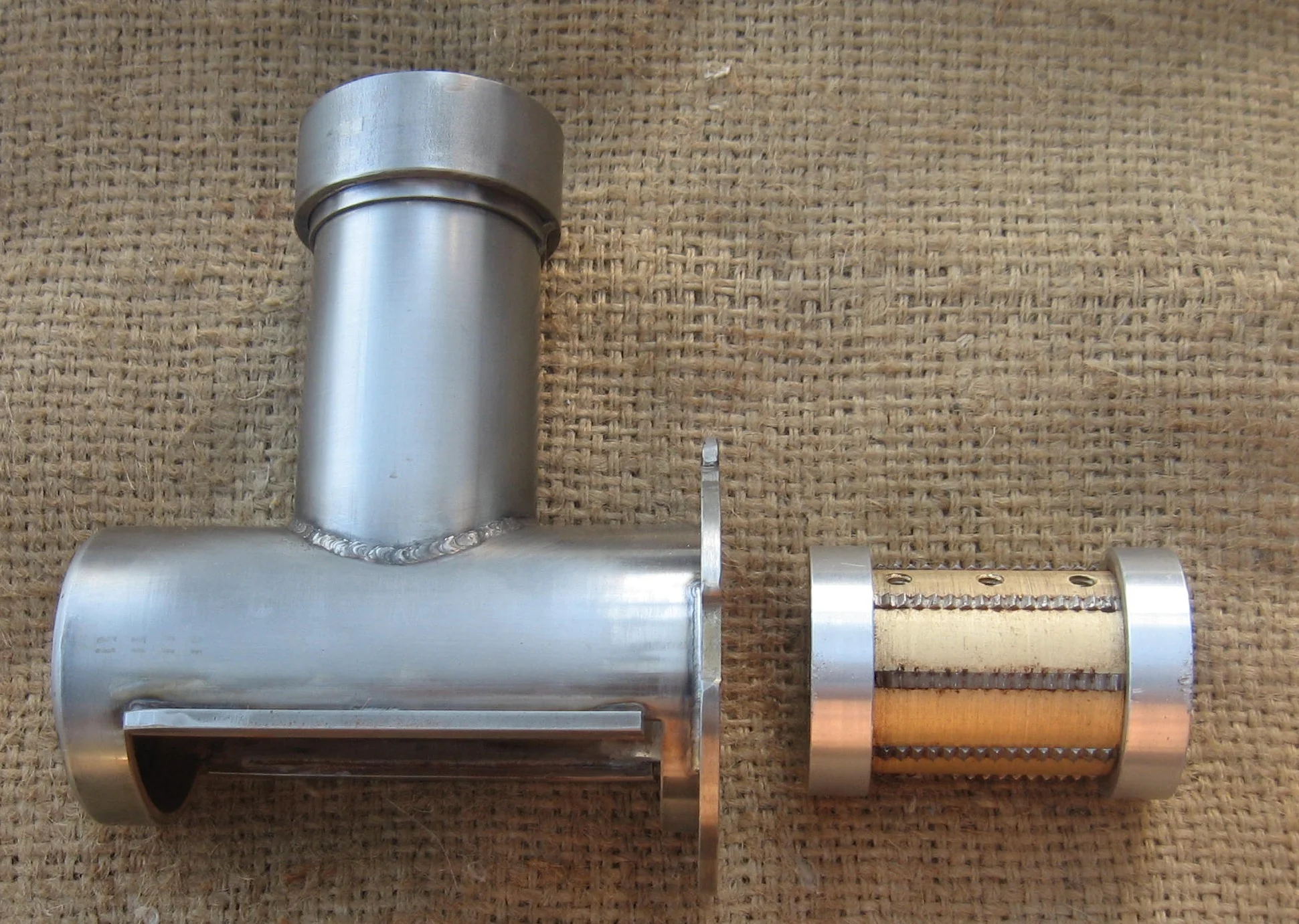

Crankandstein Cocoa mill

That just won’t work.

It is worth mentioning that I tried to make the cocoa mill work for an automated winnower. I tried for years. And there was always one more hurdle or issue to solve, one more sticking point.

I’ll detail why in a little bit.

This is interesting. Over the last month or so there as have a real upswing in the number of people asking about and wanting to use the Crankandstein cocoa mill. Yet I have not offered them in a number of years. Not since they stopped production some years back for a facility move and never responded again about starting up production again.

For those not familiar with it, the Crankandstein cocoa mill was the first good way to crack cocoa beans at home or on small scale. I developed it as a variation of a standard brewing grain mill. Regular grain mills didn't and won’t work as the gap, or space, between the rollers is too small. Cocoa beans just roll on top of the rollers without being grabbed by the rough knurling of the rollers.

Unlike many grain mills that are adjustable, the cocoa mill has a fixed gap. This is because adjustable grain mills have what is called a slave drive. This means that only one roller is driven (the master rollers), the grain is caught, pulled down, and engages the second free spinning slave roller. Unfortunately it didn’t work that way with cocoa beans. The larger beans (compared to grains of barley) didn’t always engage the slave drive so the beans just sat on top of the rollers. To address this, the second roller was geared to the first and with the action of both rollers spinning together the cocoa beans were drawn in. This gearing, since they have to intermesh, prevented the gap from being adjustable and driven at the same time. Because a single cracking didn’t quite separate the husk well enough the options were to add either a second set of rollers or another roller that worked together with one of the existing rollers. For price sake (gears are expensive) the final design was a 3 roller mill instead of a 4 roller mill.

And this is….I don’t want to quite call it a design flaw…is one of the limitations of the cocoa mill. It’s actually several of the limitations. The cocoa mill cracks roasted beans rather well and they winnow with a hair drier also pretty well. But the pieces are a bit large and a little uneven and that keeps them from working really efficiently in many winnower designs. If you pass the cracked nibs and husk through a second time that works much better for a manual winnower like the Sylph. But that just doesn’t work for an automated winnower like the Aether. You get one pass there.

Let’s talk about some of those sticking points I mentioned above and how I tried to address each one.

The first is automation. You need to hook it to a motor. But you cannot hook it to a standard 1200-1600 rpm motor. At that speed the knurling can’t grab the beans and the rollers just spin. So you need to gear it down. Your choices there are either belts, chains or gearboxes. Slow DC powered gearheads don't have enough power.

I found belts could never quite maintain the tension needed without a pretty major overhaul of the structure. Possible? Yes, but it was expensive.

Chain link was pretty good, but derailing happened a lot when used as the primary gear reduction.

Gear boxes worked pretty well, but are very expensive.

Derailing and slippage could be reduced by a large degree if you put it together with a gearbox. But at this point the whole reason for using the less expensive Crankandstein mill has gone completely away because you have added in over a thousand dollars in gears, rollers, gear boxes and motors.

But for the sake of argument, let’s say price is not a concern.

The biggest issue with this style of cracker is bean consistency. It can be made to work fantastically on beans with fantastic preparation. But when bean consistency deteriorates so does how well it works. Small beans can pass through completely and large beans often will not feed. Double beans usually pile up on the rollers until nothing is feeding through.

And then there are rocks. These are a fact of life in cocoa beans and when you hit one you need it not to destroy your system. I know lots of people hand sort, but to my way of thinking, this just isn’t viable. And I have hand sorted. Rocks get through. And when they did something always broke. Usually the very expensive gears or the gear box. I tried time and again to build in a weakest link, like a belt that would just slip, or even a slip clutch, but what happened was that the force needed to crack cocoa beans was very close to the stopping pressure needed to engage the safety features. The result was a system that didn’t break, but also would not run continuously without lots of intervention. It kept thinking it was about to break so it stopped.

I’ve actually seen some very nice crackers out there. Usually the cost was somewhere around $2000-3000 when all was said and done. But every one was always in a controlled lab setting with nice clean and even beans. I don’t know any in a running bean to bar facility. And it is worth noting I even saw one that was built like a tank. The result? It would crush the rocks and not break. Impressive, yes. But then you have rocks in your nibs and no way to remove them. Clearly not an answer either.

To me it is just a no win design.

So let’s talk about the Champion juicer for cracking and why I advocate it.

Some of you may recall when I first discovered the Champion would also crack beans I was not a huge proponent of it. I said it created more dust and the implication was more loss of nib. But it turns out that I was not 100% correct. It does indeed create more dust, but it turns out that it is husk dust, not nib dust. I verified this by lab analysis. The dust contained virtually no fat whereas powdered nib is 50% fat.

After that, it auto feeds cocoa beans a near perfect rate for the winnowers I designed. It cracks small beans and double beans plus it doesn’t need to be geared down. It’s hard to not love something that works off the shelf with no adjustment. It also does it in a single pass unlike the 2 or 3 passes the Crankandstein requires for good separation.

That is really crux of your question. The Aether Winnower was designed for the Champion. Really all parts mesh together. The height of the hopper. The introduction port. Both its feed rate and the size of the particles it produces. It just isn’t set up to handle a cocoa mill. There are not advantages to the mill and tons of disadvantages.

What about rocks? I hear you say. It’s not perfect there, but it isn’t bad. Most rocks just bounce off the high speed cutter. You can hear it, stop it, remove it and continue without breaking anything. Occasionally a small one can make it through but most of the time what happens is that it catches, and the torque limiter built into the Champion motor shuts it down without breaking anything. Worst case it breaks it into a few large pieces that are removable.

The only real drawback is that the cutter blades do wear out. To my mind this is better than breaking things. I’ve addressed this with the Deluxe cracker.

The design is basically the Champion cutter and housing in metal with 10-20 times the lifetime. Nearly the price of the highly engineered, gear reduced cocoa mill, but unlike that design, it is robust and runs continuously without constant intervention.

So there. That is why I don’t recommend you use the cocoa mill for my or any other automated winnower and why I like the Champion. And if you are doing it by hand I still like the Champion for its ease of operation. The Champion is about $15 more than the cocoa mill, but it is much faster, is already motorized and does a better job. That’s worth $15 in my book. Of course is always your choice.

On the surface the former might seem cheaper but in the long run it is no contest. The Champion is a champion and was designed for the Aether.