Level: Novice

Reading Time: 12 minutes

How can I relate this (the roasting profiles) to what happens in my Behmor, where I cannot control the temperature in subtle ways? I feel I get good roasts in it, but I am really flying blind and trusting I am getting the right temps at the right time and the right length of time. I am assuming that on P2, which looks like the best profile based on what you said this week, the 100% power brings the beans through the drying phase and at 60% or shortly before they have reach 212 (I would assume by the time I hear pops the beans are over 212) and that the ramping down of power at 60% allows the beans to maintain the momentum phase at the right slope. Does that temp increase at 90% help to maintain some momentum after it goes into cooling stage? And in the cooling stage, how much of that is still momentum and how does the cooling stage relate to the end of momentum?

I’ve received a flood of variations of this question this week. The other variation relates to convection ovens and that something seems not quite right when profiling in one. So I’m going to go ahead and address it before getting into the next two stages of Profile drum roasting.

Before that though, I would love to know what people thought about last week’s Ask the Alchemist and the introduction to the Drying phase. Unlike the week before where comments and questions poured in last week as been silent.

Let’s talk about the Behmor. In short, as is, out of the box, you can't relate anything. I tried for a couple years and the data just does not correlate. I can go really deep into why that is the case, but the end result is that unless you drill a hole in the left side wall and through the end of drum so you can insert a probe, you are doing nothing more than flying semi-blind and trusting the autopilot. You called it correctly.

What that means is that when I see you or anyone start off saying "I assume" I can just say "no". No correlation. You also can't assume or depend on the beans popping. Part of the issue is you don't always want to "ramp down". It is fully dependent on your profile goal. If I am roasting in a cold room with a heavy load on the first roast of the day I may never throttle down because the roaster is doing it naturally by absorbing heat that would normally go into beans....and I only would know that by knowing and tracking the bean temperature. Nothing else correlates.

“But what about the chamber temperature? Can’t I relate that? I have noticed it goes up as the beans get hotter.”

Yes, I have noticed that too. And I meticulously tracked the bean temperatures and the chamber temperature in both a Behmor and my Royal Roaster. I processed and graphed and manipulated the data a lot. And sure, there is a trend. But you can find a trend in many things but that doesn’t mean you can use that trend for more than very general predictions.

Maybe you have heard of a common one. It’s called weather prediction.

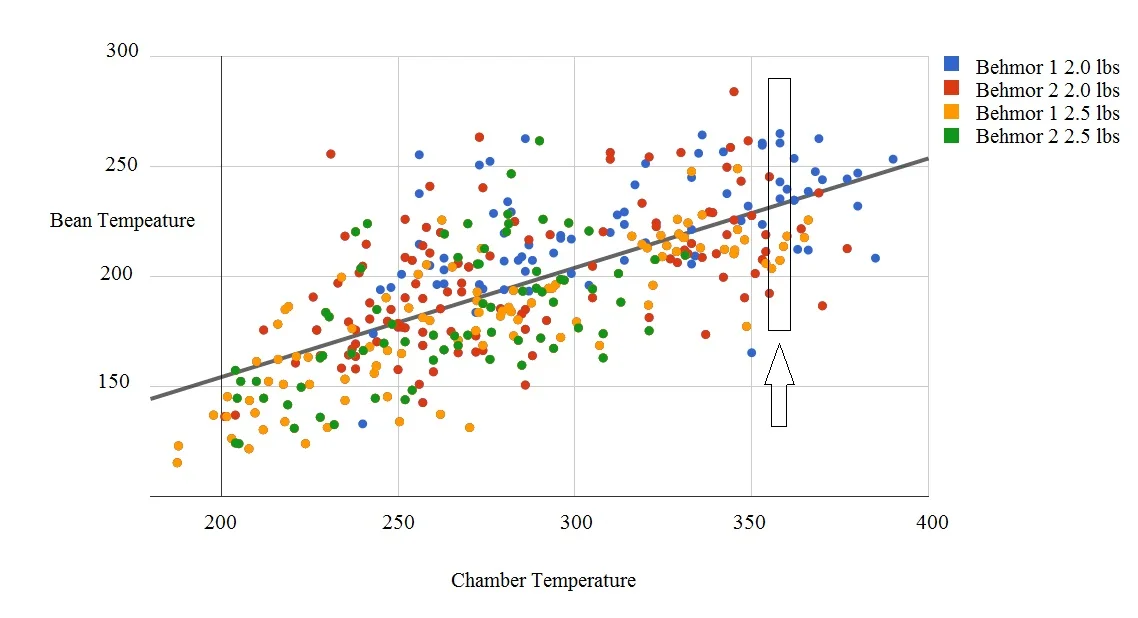

I’m not joking. Yes, I made a joke, but it’s also a valid point. Have a look at this collection of data. It is the result of running the same test over and over.

Yes, there is clearly a correlation. But you can’t do anything with it.

Let’s try it. You have loaded 2.5 lbs of beans into your roaster. You roast.

The chamber says 360 F.

What temperature are the beans?

Well, the constructed line says about 225 F. But in one roaster the beans were actually 205 F, yet in the same roaster, with the same load, at another time they were 212 F.

Maybe that isn’t too terribly bad, but with a load of 2 lbs the beans could be anywhere from 230 F (under roasted) all the way to 260 F.

And there is absolutely no way for you to know which it is. I’ve even tried linking it with beans popping, but some beans pop at 235 F, some 250 F, and some never pop.

See what I mean? There is a trend by no usable correlation.

The same exact uncertainty of basing the bean temperature on the oven setting occurs in ovens, even convection ovens. And it is even worse than just not being able to know where you are in a roast. It is really hard, if not impossible to get a truly even roast.

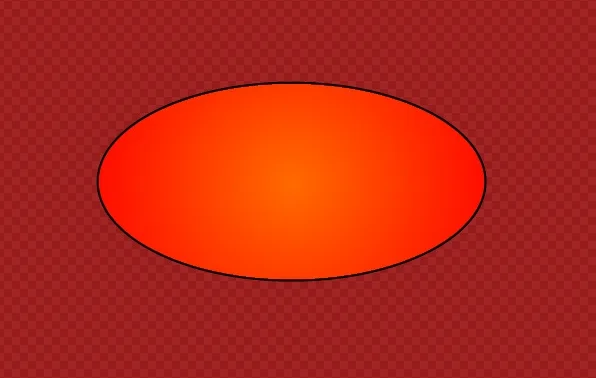

In a rotating drum roaster, by nature of the beans tumbling and moving constantly, cocoa beans have a pretty uniform surface temperature, so get a predictable internal temperature gradient. Something like this.

That's pretty even. A little cooler to the center, a touch warmer at the long ends, but overall even and consistent.

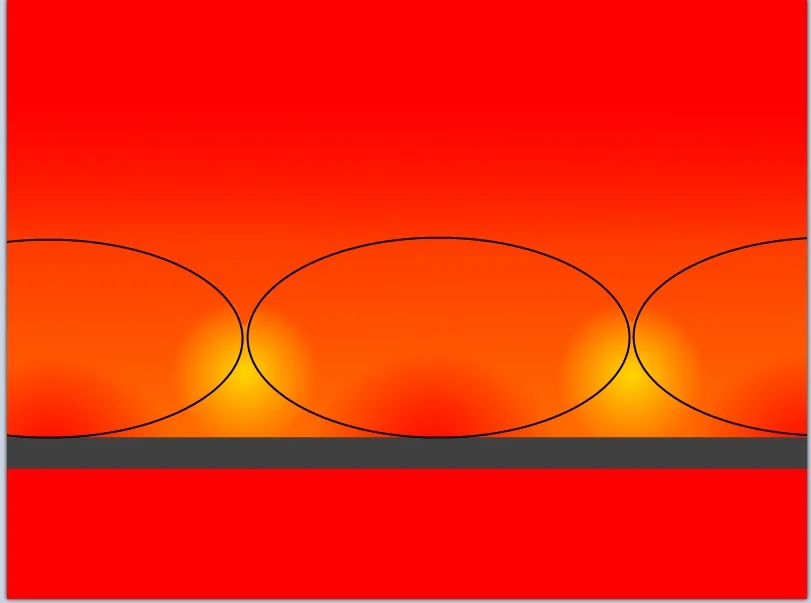

In an oven, when the cocoa beans are on a sheet pan, the surface temperature of an individual bean can vary pretty wildly. The tops of the beans that are exposed to the air are seeing one temperature. But the bottom of the beans are in contact with a surface and regardless whether it is metal or glass it is going to conduct heat differently than the top of the bean which sees air. Sometimes it may be hotter, and other times cooler. There is no way to tell.

Then there are the edges that are most definitely going to be cooler than the top or bottom simply because each bean is touching another bean which by nature of not seeing the air or the bottom of the pan will be substantially cooler. I suspect the internal temperature profile could look like this.

Even if you are stirring a lot there is a high chance you are going to see lots of variation.

Some of the bottoms got extra roasting, many tips are very under roasted and overall it's just a mess.

And lots of variation means it is difficult to reproduce. I know of only one reliable way to oven roast. It is what a lot of people refer to as “low and long”. By keeping the temperature very low you don’t get hot spot (or not as many) and you do have enough time stir them often enough to make them reasonably even.

Which roast would you prefer?

I need to end by making it clear that I am not saying I don’t like the results of some oven roasting. I had a great conversation this morning with a friend and chocolate maker who was really loving the results of roasting 45 minutes at 225 F. And make no mistake, I love his chocolate. It is fantastic.

But he also voiced frustration about the amount of work it took to get there and every bean took lots of effort. That it literally took a full bag (120 lbs in this case) to work out the roast. It is horribly time consuming and wasteful. That hurts my soul. And it hurts that he can’t share his roasting technique in any way that allows someone else to replicate it. His load, his oven, etc mean there are just too many variable. Basically, as I understand it, he kept trying temperatures and times until it tasted right, and even then reproduciblity was a challenge.

Early this week someone sent this to me. “I want to roast low and long. How long should I roast?” I am completely unable to answer that in any meaningful way. I desperately wanted to answer meaningfully but the only answer was “until it tastes like you want it to”. And that answer really sucks. The maker above roasted 45 minutes. I tried that in my oven and it was under roasted. But another maker I spoke with roasts for 75 minutes and that is right for their conditions. All in ovens. All at 225 F. Madness.

And that is how it has been for years. “Experiment, see what works for you”. Again I say madness.

My goal is to change that.

So my long winded point is that to me part of what makes a roast good, aside from the chocolate it produces, is it’s reproducibility, it’s ability to be shared and that it can be systematically manipulated to produce different flavors.

Oven roasting and black box roasters like the Behmor rather fail there.

I'm really sorry, but you just can't relate Behmor profiles or chamber temperatures to your roast's progress.

Drum roasting while measuring bean temperature succeeds and why that is what I will continue discussing next week.