Level: Apprentice

Reading Time: 13 minutes

While ordering my cocoa beans from a supplier, I came across a couple of unfamiliar terms known as 1. Bean count 110/100gm and 2. Fermented bean percentage 85%. Kindly shed some light into this topic and please let me know if these are acceptable values for making good quality chocolate.

There is one really easy question here and one that has a lot of baggage and information before I can really answer it in earnest.

Let us get the simple one out of the way. For some reason, and I think I know what it is, bean count is an odd way to measure of how large or small beans are in a batch on average. You weigh out 100 grams of cocoa beans and then count them. That is your number. I personally don’t like this system as it is kind of the opposite of what you expect. If you have two bean counts, 110 and 90, the 110 are the smaller beans. So something like Wild Bolivia Itenez where the beans are tiny, the bean count is around 130 meaning it takes 130 beans to equal 100 grams. Guatemalan Cahabon on the other hand are huge coming in at a bean count of 70 beans/100 grams.

For years I have wanted to flip this around so the larger number goes with the larger bean but sometimes it just isn’t worth fighting against tradition. If you are wondering, what that would look like would be:

Wild Bolivia Itenez 100 grams / 130 beans = 0.77 g/bean

Cahabon 100 grams / 70 grams = 1.4 g/bean

Yeah, that feels so much better, but alas, that isn’t what the standard is. That said, I do get why they do what they do. It is protocol and requires no need of math. You measure a set amount (100 grams) and count and you are done. It keeps the procedure consistent and I really can appreciate that.

The way more complex conversion is about fermentation levels and another tradition, the Cut Test. Definition time.

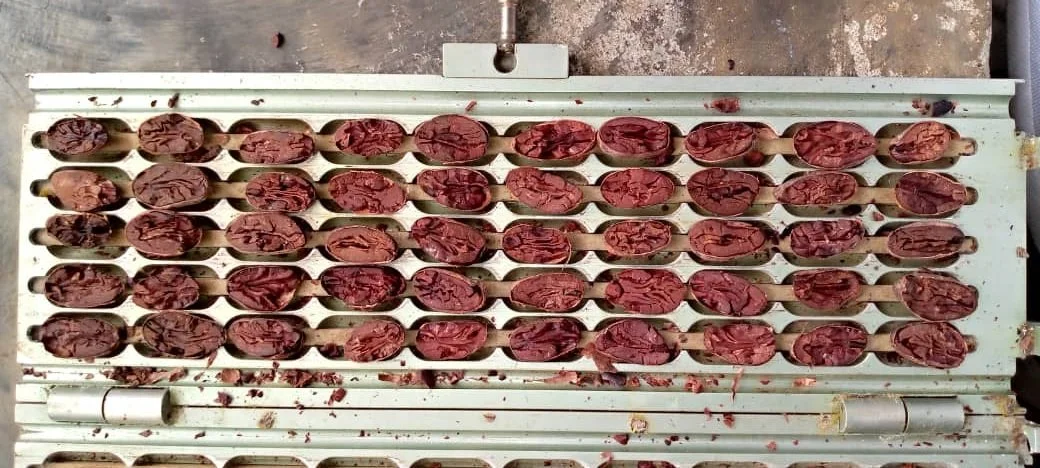

A Cut test is just what it sounds like. You cut in half a statistically significant number of beans and make a judgement call if they are fermented, partially fermented, unfermented or other. This is usually just done with a knife.

Cut test

No fissure

White beans

One of the big keys here is that this test is done in origin during fermentation (more on this later). I’ve seen spot tests done with 10 beans to get a feel for how a fermentation is progressing and as you get close to your target (foreshadowing here) more beans are done to get a more accurate value. A device called a guillotine is often used to do 50 beans in a shot.

Cocoa Bean Guillotine

Generally speaking, at least 70% of the beans need to be fermented to be considered acceptable. What is acceptable? Well, that is where judgement comes into play. Raw cocoa beans start out either purple or white (again, generally speaking) and are uniform. During the fermentation a hold of bacteria, yeasts, and other microbiota ferment the beans and various chemicals begin to permeate the cocoa beans. As this occurs, the beans start to darken/shift into brown and fissures start form (these are where beans naturally crack into nibs) and the endosperm (what would be the stem if sprouted) shrivel up and die, turning into the germ/radical. The thing is that all the beans don’t progress perfectly consistently by the nature of being in different parts of the fermentation box, seeing different temperature, being exposed to different levels of the fermentation byproducts, etc, so at any given time some beans will be more or less fermented than others. When 70-85% are fully brown, have complete fissures and the endosperm is dead, the fermentation is considered complete and the fermentation is stopped.

Once the beans have been removed from their fermentation boxes and spread out to dry, some producers might do more cut tests to continue to check progress and finally give the value you see up above of 85%. Up above I also gave a nebulous comment about “other” and those can be moldy, slaty (not marked with fissures, but grey (slate colored) and slick), germinated (the germ and/or cotyledon are still there) or insect damaged.

I hardly see it but in commodity grade beans I often see either specification sheets listing these or requirement specifications listing values that cannot be exceeded. Various organizations like the Federation of Cacao Commerce (FCC) and the International Cocoa Organization (ICCO), have made it a requirement for large companies to use standardized cocoa. The thought is that cocoa that is all fermented to the same point should all taste approximately the same and buyers can measure samples against the specification sheets and accept or reject based on those results. Flavor is hardly ever a consideration since they’ll generally roast the F#$K out of it, add way too much sugar and conche it to h@!! so it appeals to the general public. We of course have higher aspirations.

Often, they specifications are evaluated with greater or less than values. For instance.

Fermented > 70%

Slaty < 5%

Moldy <3%

Insect damage <2%

Germinated <5%

Broken <5%

But this is where things start to go awry. This test was never meant to be used as a way to define quality. It was used to measure consistency, fermentation progress and minimum or acceptable quality. And that is key and how cut tests don’t work well at all for specialty cocoa and the actual quality of a sample.

Our human brains are funny and wondrous but they are also prone to bias and perceived correlation and relationships that don’t exist.

They want beauty and consistency.

They want to believe that If you can count it, it must correlate

If one level is good or acceptable, higher must be better and ‘perfect’ must be best.

The best look must mean best flavor.

Unfortunately, those things are just not true and I’ve seen it personally over the last 20 years in a variety of forms.

Tools generally have a purpose and using a tool outside of it’s intended purpose might work on occasion and something might even show a new use for the tool, but too often, repurposing a tool for another job leads to less than great results.

How that relates is that cut tests are a viable way to check for defects. They are a nice way to evaluate the level of fermentation, and help the farmer/fermentary to keep an eye on health and progress of the fermentation in a batch of cocoa beans.

For all that, the cut test is a nice tool. But for evaluating how a bean might taste or if bean X with this cut test will taste better than bean Y with another cut test? It is just not a good tool at all.

Why? Here are some observations that I’ve seen over and over as the bean to bar industry has grown.

I used to receive samples that did not look all that great and had mediocre cut tests but had a fantastic flavor. I could usually count on 1-2 really stellar samples a year. Then beans started to look and test a little nicer….and maybe I would get 1 stellar sample a year. Somewhere along the line it became chic and the thing to sort beans for appearance and people (I mean makers) started turning down beans on appearance so producers started sorting for appearance in origin and little by little really stellar and stand out beans and chocolates became pretty rare. Mind you, there are good beans out there, but I literally can’t think of a single pristine and cut test perfect bean out there that utterly blows me away. The last two beans that knocked my proverbial socks off were Ecuador Cayapas and one from Nigeria. Both had the deep, rich, complex heady fruitcake like aromas and tastes and both had flats, slaty beans, doubles (where beans stick together) and even black beans.

That is my pretty standard rant about sorting and not judging a bean by appearance and really, we are talking cut test, so let’s talk about a bean I carried at one point from Bolivia. It was a little rough around the edges. Probably 75% fermented, 2% slaty, 0.5% black and I really loved it. It had this deep, rich and complex chocolate flavor, pronounced blueberry plus undercurrents of macadamia nut and supple leather. I carried it 3 years running….and then because it got popular makers started requesting cleaner beans and higher fermentation rates, because if 75% is great, 80% must be spectacular. Right? Utterly wrong. The depth of flavor went away. The blueberry went away. It was still chocolatey but there was now this layer of something gamey that just didn’t set well so I stopped buying it. A note about gamey. I mention beans are at different points within a fermentation. What that means is that as you push the fermentation level higher, some beans go past optimal and another word for that is over fermented or also rotten. A little over fermented and it is deep, and alluring and enticing. Think about some lilies. They are all that….until they are not and then they are kind of stomach churning. Same thing with over fermented beans. It is a balance act.

One last one. At some point a lab in Brazil reached out to me to evaluate some super clean, even and hyper consistent fermentation and drying techniques. The sent me half a dozen samples, one of which was a control and various other permutations. Keep in mind that although I could visually tell which was which when roasting them, I blind tasted them. What I found was that the more perfect the cut test, the worse the chocolate tasted. They were just flat and consistent and boring….but oh so beautiful.

Now, before you get the wrong impression, I am NOT saying that a clean and consistent fermentation and cut test is bad, but what I am saying is you can’t use that as your guiding principle if your goal is flavor.

So what good is the cut test? Many producers use them as an indicator of flavor, so they can replicate specific profiles. But this is the key. The cut tests on its own won’t tell you much specific flavor notes. When I’ve seen them used best is when the fermentation is done and cut tests are done along the way to give a way to track subsequent fermentations.

A particular color of brown and a certain look to the fissures may be considered good, but to apply it across the board to all cocoa like they do for large commercial chocolate ignores that different combinations and degrees of fermentation can lead to different and unique flavor profiles and only by trial and error can you determine what combination, for a given cocoa, yields the flavors that are sought after. And note, I did not say best. Just like there is no best cocoa, no best roast profile or best chocolate, there is no best fermentation level. More is not always better.

To add to the complexity, many farms have mixed varieties of cocoa and can have a hard time hitting a consistent cut test goal. Different varieties react to fermentation in different ways. If a fermentary simply looks at a cut test, out of context of past history, the batch may be dismissed as bad, under or over fermented, when in reality it could be really stellar. But they would only know that by having a set of data from previous cut tests that correlate to the resulting flavor profile of the chocolate produced.

And this really brings us back to why I don’t do a cut test. I’m not in origin, I don’t have control of the fermentation and there is literally nothing for me to be gained by the cut test data alone. On the other hand, if I’m presented with 3 samples of beans where a producer tried three different fermentations, I can do what I do best and make them into chocolate and provide them back with that information so they can then hone what they do best, that being fermentation and correlating the flavors I find with the cut tests data they have. At that point there is a complete cycle of test, feedback and hopefully the zeroing in on a cut test/fermentation that can be done consistently that produces a great and dynamic chocolate.

So there you go. If you are looking at purchasing beans, 85% fermentation in isolation tells you basically nothing, which is why I never give that data. It might make fabulous chocolate and it might make something you would not want to ever eat again.

If you have found a source that produces at 85% and you like it, and the next year it is again 85%, there is a higher chance you’ll like it again assuming they were following a protocol. Does that mean you like 85% fermentations? That would be a dangerous conclusion to draw but people do it all the time.

On the other hand, if you are a producer and know you want an 85% fermentation based on previous experience and the cut test is used to evaluate the progress, health and stage of the fermentation, then it can be a critical tool for consistently great beans.

You just have to remember that cut tests are not an accurate indicator of what is good or bad cocoa. They are a part of a full system and must be used as such.

Use the right tool for the right job.